|

|

|

| |

|

| |

|

|

Welcome to buy our products!

Please fill in the required product conditions form

below,We will develop effective and feasible plan

to you,We have received your order will respond

in the shortest possible time. |

|

|

| |

|

|

Home>>Products |

|

|

|

| Auto Taper Rolling Bearing Grinding production Line | | |

¡¡¡¡Auto Taper Rolling Bearing Grinding production Line--Combines the most advanced production technology level, made independently developed by the Company with a number of product patents. Efficient automated connection technology greatly enhance the production process and equipment efficiency, reduce labor intensity and improve equipment automation.

¡¡¡¡Automatic grinding to connect the actual layout, production processes and machine tools based on customer requirements and layout of the host location to determine the size and import and export,Automatic feeding machine, elevator, chain conveyor, demagnetization washing machine, automatic testing machines, supplemented by material processing equipment, Road connecting mill, together with the electrical control system, automatic detection for grinding, cleaning and assembly-line intermediate demagnetization process transportation of automation line production, can improve product traceability and minimize the outflow of defective products. |

|

Main function of indicators£º

1.Specification: diameter ¦Õ20 ~ ¦Õ55mm diameter£º¦Õ30~¦Õ90mm

2.automatic transmission connection speed: <8s / a

3.demagnetization cleaning, improving processes to complete before the moral quality indicators.

4.with testing and feedback capabilities.

5.up 10-15% of production efficiency.

System Components FEATURES£º

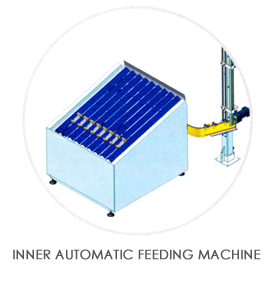

1.Automatic feeding machine£º

A. Storage capacity: diameter-¦Õ30mm, width = 15mm product can store 424 products;

B. Feeding speed: <8s / a;

C. No change in the change within the provisions of tooling.

2.Hoist£º

A. aluminum extrusions;

B. Chain Drive upgrade;

C. No change in the change within the provisions of tooling.

D. continuous, slow product upgrade, run stable.

3.Level conveyor£º

A. Conveyor speed: <8s / a;

B. flat top conveyor plate;

C. aluminum alloy frame;

D. In the context of change need to replace the provisions of tooling.

4.Demagnetization washing machine£º

A. Residual magnetic flux: ¡Ü 0.3Tm;

B. spray cleaning method structure, across the board for liquid concentrate;

C. Air dry.

5.Machine outside the detector£º

A. automatic diameter detector, configured by the grinding machine including circle exports;

B. diameter test results data can be fed back to the client host, to improve precision;

C. At the same time to complete internal diameter, diameter taper, diameter, roundness checking;

D. Check the product of bad products, bad according to the types of discharge.

6.Slide£º

A. Material: SUS304, t = 3mm/5mm;

B. No change tooling for type, just do a simple setting adjustment.

7.Electronic Control System£º

A. Single and connection with communication;

B. feeding a single count and count function;

C. PLC programmable control, touch screen display operation.

|

| Outline£º |

|

|

| |

| | | | [Back] [Print] |

|

|

|

|

|

|

| |

Copyright

© WUXI SUNLIGHT AUTOMATIC EQUIPMENT CO.,LTD. Allreserved.

Add£ºBuilding 22, No. 35, Yanqiao Road, Yanqiao Industrial Park, Huishan District, Wuxi City Contact£ºMr.Xin 13771472155 Fax£º0510-83571708 Http://www.wxshenglan.com |

|